A floor that is continuously exposed to the elements must have that something special; water, wind, cold and heat, perhaps combined with heavy loads of machines or cables. Herculan self leveling resin floors are like a duck to water on board of ships and platforms. Developed and produced to deliver under the most extreme conditions, they form a solid base worldwide.

PROJECTS THAT WE ARE PROUD OF

References Shipdeck flooring

OUR IN-HOUSE R&D MAKES THE DIFFERENCE

SHIPDECK FLOOR INNOVATION&DEVELOPMENT

A BETTER SHIPDECK FLOOR THROUGH INNOVATION

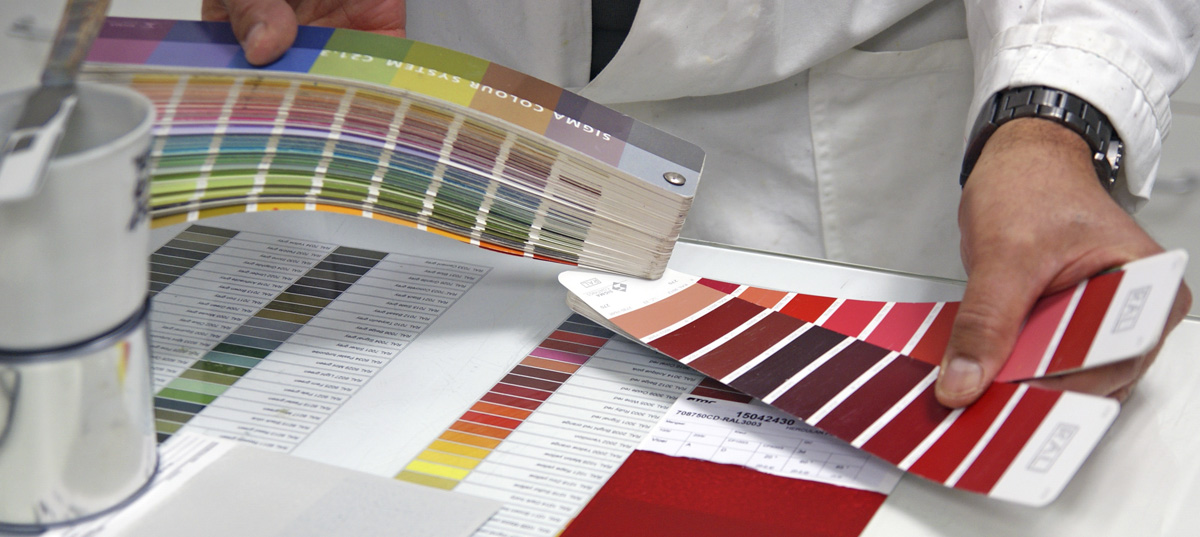

Without innovation, there is no future. Herculan has been motivated by this belief for over 25 years. Through the years, our in-house R&D department has accrued a wealth of expertise when it comes to the characteristics of synthetic floors and the specific application thereof. Herculan puts this knowledge into practice in its own production and installation of shipdeck floors. This means that everything is done by the same party, and you have one contact for the entire process.

FROM RAW MATERIALS TO END PRODUCT

SHIPDECK FLOOR MANUFACTURER

NO CONCESSIONS WHEN IT COMES TO QUALITY

The good reputation of Herculan shipdeck floors is partly based on its strong focus on quality. Thanks to the know-how of our in-house R&D department, Herculan products are of a constant and high quality. The composition of a shipdeck floor is a complex combination of raw materials, that all have their own specific characteristics. This makes the production a meticulous process. It starts with the strict entry check of the raw materials; only the very best quality is good enough to be at the basis of a shipdeck floor that bears the Herculan name.